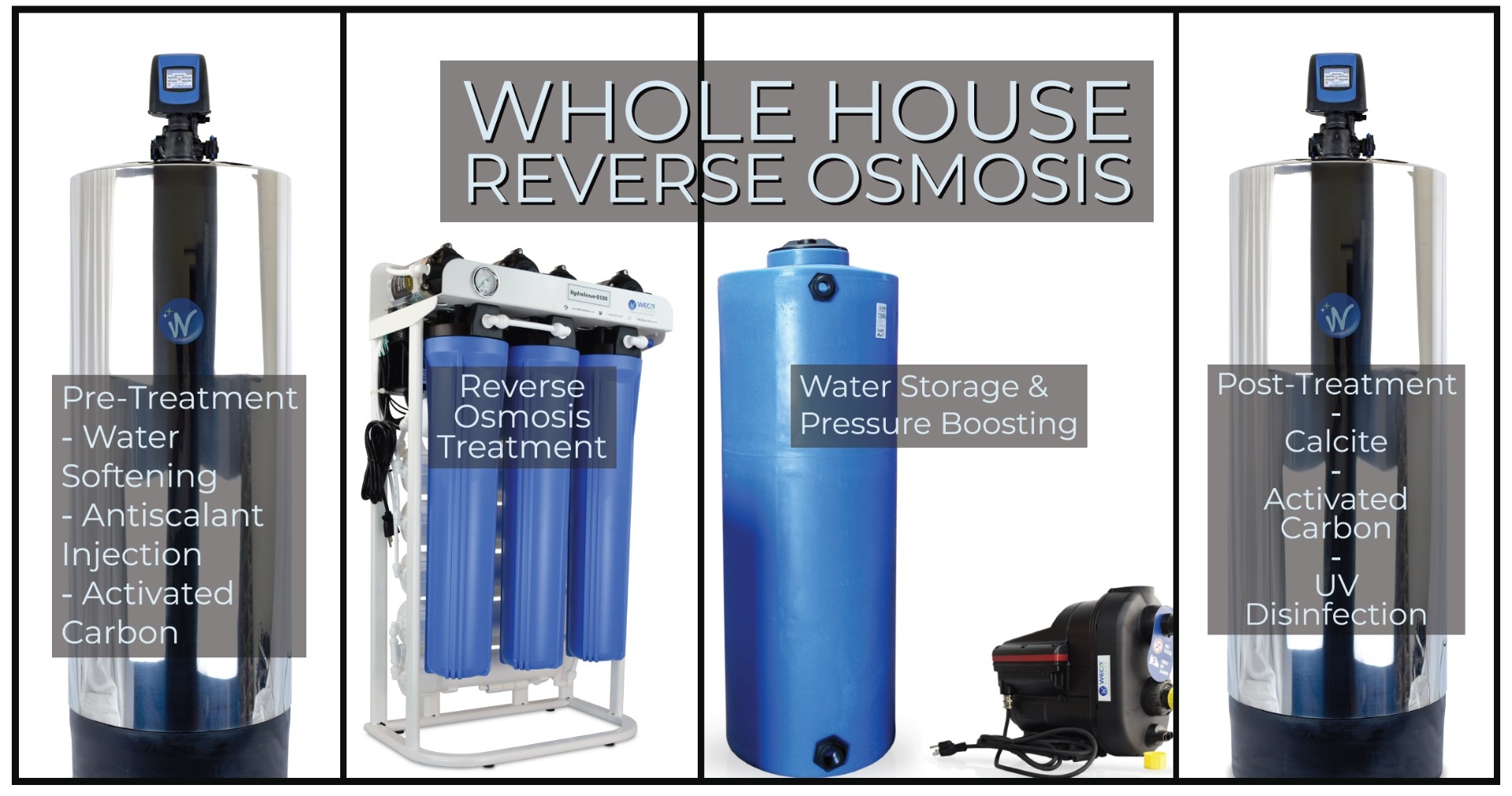

Is Whole House Reverse Osmosis Right for You?

The article will aim to help assist you in the understanding of determining the water processing equipment you may need while also providing clarification on some of the small details within determining the correct equipment and chemicals to use within your house or place of business.

To first begin we can discuss why water processing is so important. I don’t have to tell you the importance of water as it is used from everything from drinking water or consumable products, to use within energy systems, boilers and many other applications. The one trouble however that water poses is that it is a universal solvent. It has the ability to dissolve many different chemicals or substances. Now depending on the substance, it may dissolve more or less but most things dissolve in water to some extent unless hydrophobic in nature. This poses a problem because there are many things we don’t want in water if we are to use it. Most everyone would not like to see slime or dirty water coming out of their faucet when they fill a cup to drink. But sometimes it’s the things we cannot see or know in water that are also dangerous. But for consideration of water processing units at a residential level it’s good to consider the different types of inlet water sources.

The most common inlet water source to most people is city water. The water you get that is processed by the city for our use. They do some amount of processing but sometimes it’s not to the levels we would prefer. They tend to get big suspended solids out of solution using flocculation, a method of binding big undissolved solids basically into a large ball then letting gravity drag that ball of material to the bottom of a separation tank for removal while the better water flows further into the system. City water processing is something similar to figure 1 below.

Figure 1: Large reservoirs for the purpose of removing large suspended solids.

However, the city doesn’t go to lengths to remove everything. They always have certain ppm regulated limits of substances and chemicals that if they stay under they can provide that water without getting fined. So let’s discuss what we as a consumer can do to help in our own way to provide water processing so we always have good water to use for ourselves that isn’t dependent on the city.

So, when considering what is needed within our system to process water it’s good to know what is in the water that isn’t preferred. To do this it is good to take a sample of water in a clean bottle and send it out for analysis. They are usually a few labs in every state that can do a water analysis and provide you a breakdown of everything in your water. But we are concerned about a few key attributes. Because at the heart of a good water processing system is usually a reverse osmosis unit which we will call an RO for the rest of the article. It does the brunt of the work and needs the proper pretreatment to keep it in good working condition.

One major material we are concerned with is hardness. If you are like me, I am in an area that has very high hardness in the water. This means the water has lots of calcium and magnesium in the water. You can usually see hardness scale on your glass shower doors because as you take a shower and the water that splashed on the door is dried it leaves behind the dissolved material in the water and the usually culprit is calcium and magnesium. These substances cause trouble because another common material in water is carbonate. When you combine these materials to make things like calcium carbonate, it can scale your RO and require further expensive maintenance to continue processing your water. Scale is essentially any substance that can precipitate out of the water to form an undissolved substance that will essentially clog your RO. A picture of calcium carbonate is below in figure 2.

Figure 2: Scaled industrial RO membrane

As you can see the membrane has lots of material that precipitated out of solution and has deposited that material all over the membrane. The water has to flow in those small spaces between the rolled-up membrane to be able to process the water. When it gets all clogged up you can imagine how much harder it will be to process that water.

So, to avoid this headache of scaling your membranes because of the hardness in your water. If you do live in an area with high hardness it is good to get a water softener. A water softener is a vessel with resin that is aimed at removing positively charged ions like calcium and magnesium and holding them on the resin bead. In exchange the softener resin discharges sodium in its placed which cant scale a membrane. But as you can imagine there’s only so many ions of calcium and magnesium the resin can take before its overloaded. So, we do have to regenerate the resin when it gets all used up. We do this by providing it a high concentration of brine (salt water) to replace the resin that has remove calcium and magnesium for sodium again. The whole process of water softener is to trade sodium for calcium and magnesium, regenerate the resin to put sodium back onto the beads and then do that process all over again. By doing this water softening we are getting rid of the chance for the membrane to get clogged with scale and require cleaning the membrane or replacement of the membrane.

Some cities however don’t allow discharge of highly concentrated brine. So, if you need a softener but the city permits you from doing so we have another option. This option is a chemical known as antiscalant. It is a substance that when dissolved in solution at the proper PPM that it will not allow the scale to form while you process the water. This assists in processing the water while not scaling the RO unit and not discharging highly concentrated brine to the city water system and getting fined in the process. There is some water processing software out there but to avoid the headache of doing the software simulation, it is best that if this option is needed to work with your chemical provider of the antiscalant for the proper dosage rate.

Another form of pretreatment to an RO is known as an activated carbon filter. This activated carbon resin is essentially a carbon rich material that was treated with very high temperature steam. When doing so it made the substance very porous. This porous resin can trap substances in those small holes made in the resin. This assists in many efforts such a removal of total organic carbons (TOCs) like urea, chloramines, chlorine, silica and many others. But for the purpose of pretreatment, the most pronounced removal that is favored is the removal of chlorine. Chlorine is unfavorable for ROs because it can react with the membrane to essentially punch holes in the membrane. As you can imagine when you punch holes in something it won’t remove everything it needs to and will let unfavorable substances through the membrane. But this is also a trouble because chlorine is used as a biocide. It helps avoid any biological growth in the water that could make the water unusable for residential use. But since most residencies use their water daily and many times per hour. The water won’t be sitting long enough to grow any biologicals so usually it isn’t too big of a trouble to remove the chlorine since water will always be running in your house.

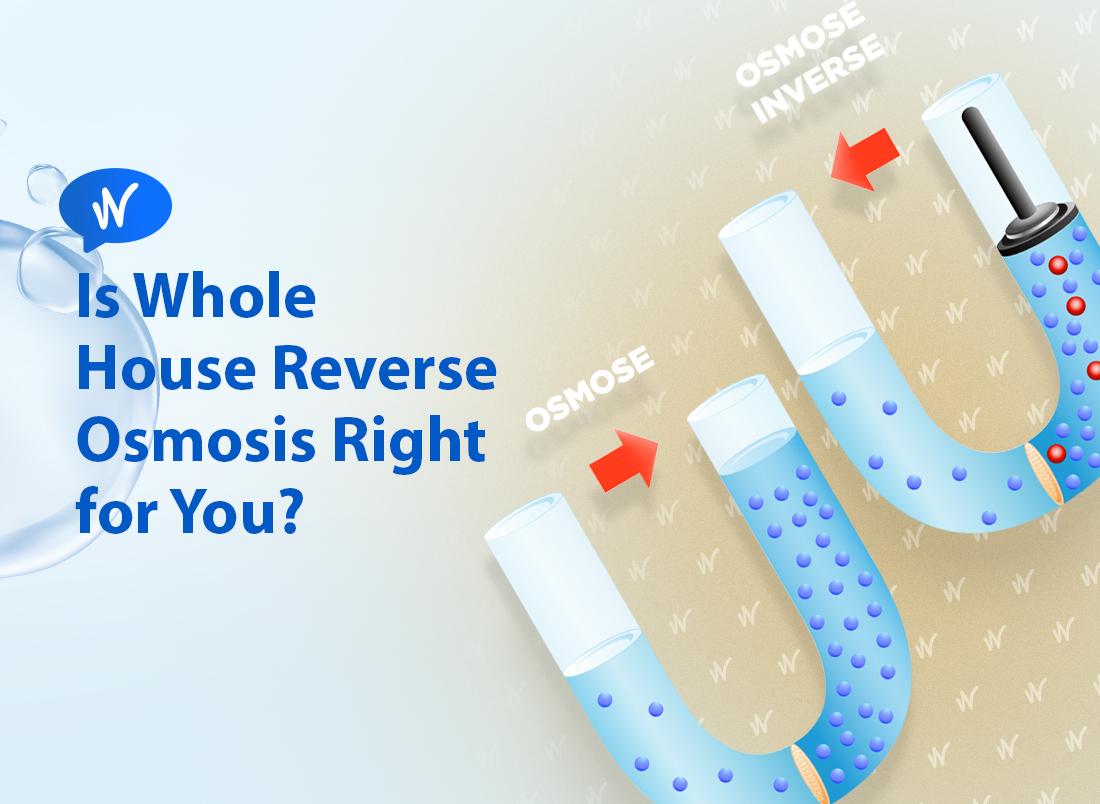

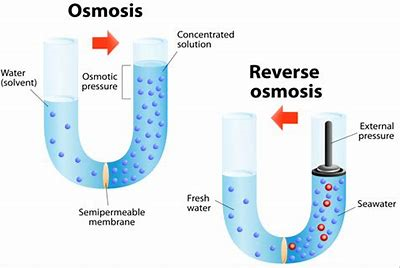

Lastly, we will cover the bread and butter of a water processing system, the reverse osmosis system. To cover reverse osmosis, it would first be good to understand what osmosis is. If we refer to Figure 3 below we can explain this picture and understand the processes of osmosis and reverse osmosis.

Figure 3: Illustrates a ubend of a pipe with the bottom of the ubend having a semi permeable membrane. The left picture is without a piston for pressure and the right has a piston to provide pressure.

If we look at the above picture we can explain osmosis and reverse osmosis. Osmosis is the nature of water to move across a semipermeable membrane (semipermeable meaning it only permeates a few substances but not all) in an effort to balance the number of dissolved solids in solution. Nature always moves towards balance and it can be seen here. However, since we want clean water we can do the reverse process. By applying pressure which is shown at the right part of the picture with a piston, we are able to apply energy to the system and push the water through the membrane to make clean water and discharge the dirty water. It is very important to remember RO does require that we discharge some water. We have to have water that will contain the dissolved solids, or the RO will have lots of scale on it just like your shower door. If we produce all the water to product and leave none as concentrate, all those materials that we wanted to get rid of will instead either be forced through the membrane and still end up in the water or it will eventually reach its saturation limits in water and start precipitating out of solution and scaling the RO. It is very important to discharge the small amount of water we need to so we can ensure our unit last a long time with little to no maintenance.

Now that we understand that we can apply energy in the form of pressure and perform reverse osmosis to make clean water we can apply this on a bigger level. As you saw earlier the RO unit isn’t a u-bend. They make fully contained membranes that we saw in figure 2 that go into pressurized vessels and produce clean water. Instead of having a small part of a semi permeable membrane. We make big sheets of them and roll them up. Then water flows next to the membrane and due to the pressure, it permeates the membrane and flows around the rolled-up membrane to product and can be used when it comes out as product. A reverse osmosis unit rejects many types of materials that are unfavorable in water and is the best form of treating water for residential use. I can’t make a list of all the substances it rejects because it would make a list with as many words as I have already written but it will give good clean water for your use.

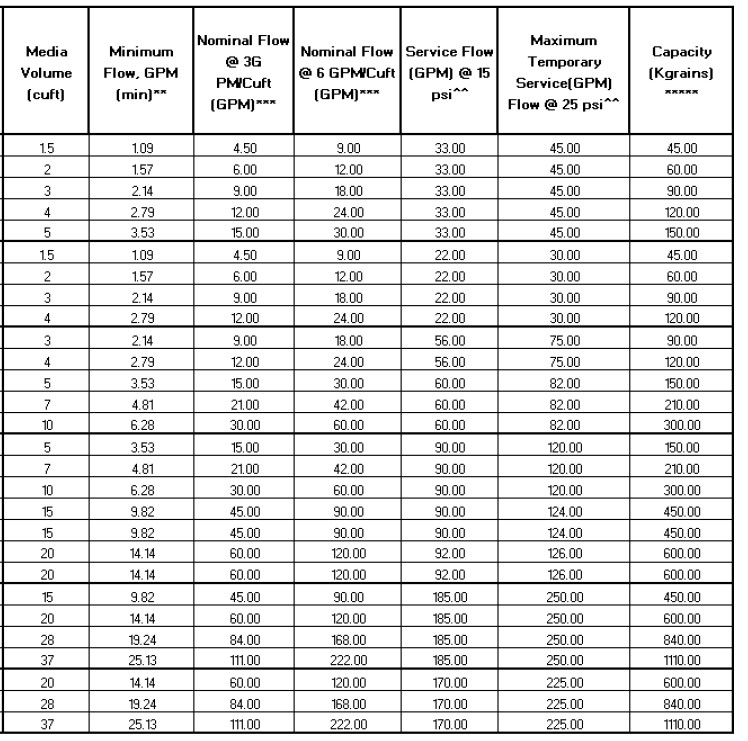

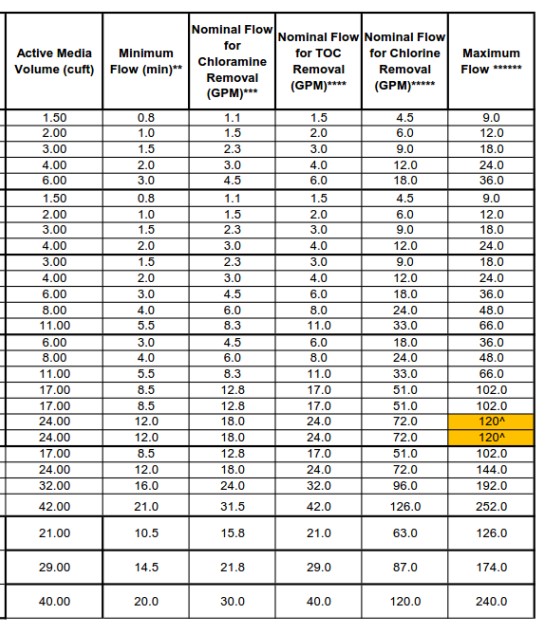

To recap, we have covered that we can use a softener to remove calcium and magnesium to protect and RO from becoming scaled. If we are unable to use a softener that we can get the chemical called antiscalant and inject it into the water to stop from having high hardness water scale the RO. Remember the correct dosage rate can easily be determined by the chemical provider so let them help you by providing them with your water analysis. We also can use an activated carbon filter to remove the chlorine and other materials to protect the RO membranes. Then we can finally process the water with an RO to get very clean water out for our residential use. If you want to learn more about water processing read more articles provided for education on water processing. Below I have provided tables to size tanks for softeners and carbons filters.

Softener Tank sizing chart for media and nominal flow:

Activated Carbon Filter Tank Sizing Chart for media and nominal flow:

To get a better picture of the filtration systems available for your water analysis, I encourage you to visit wecofilters.com and get in touch with a WQA certified water specialist. Consultation is free to all customers.

Matt Peiris is a senior application engineer for WECO Filters. He can be reached at matt@wecofilters.com.