Shedding Light on Water Purification: The Role of UV Treatment

Ultraviolet (UV) treatment is a popular technology for purifying water of common bacteria such as E. Coli. and coli-forms by using radiation emitted at a specific wavelength of 100 - 400 nm that permanently damages the DNA of bacteria and viruses, rendering it harmless. UV is a preferred treatment option in many situations to using chemical disinfection with sodium hypochlorite, that can create harmful by-products and impact water aesthetics, including taste. We explore some of the key features of how to select a UV system, including sizing a system, how UV performance is measured, and what parameters in water can affect your UV system.

Common types of UV processes:

Many older UV processes use open channels with UV lamps racks installed vertically, where the water flows perpendicular to the lamps. Whilst these installations can enable easy access for maintenance of the lamps the disinfection performance can suffer from variable water levels and hydraulics that create 'dead spots' within the channel where water may not be treated.

The current best practice UV system is a closed-vessel type with UV lamps installed parallel to the water feed, such as the POLARIS series. The advantage of this type of UV is significantly reduced size and UV dosage to a consistent volume of water that also requires fewer lamps (lower upfront and operating cost).

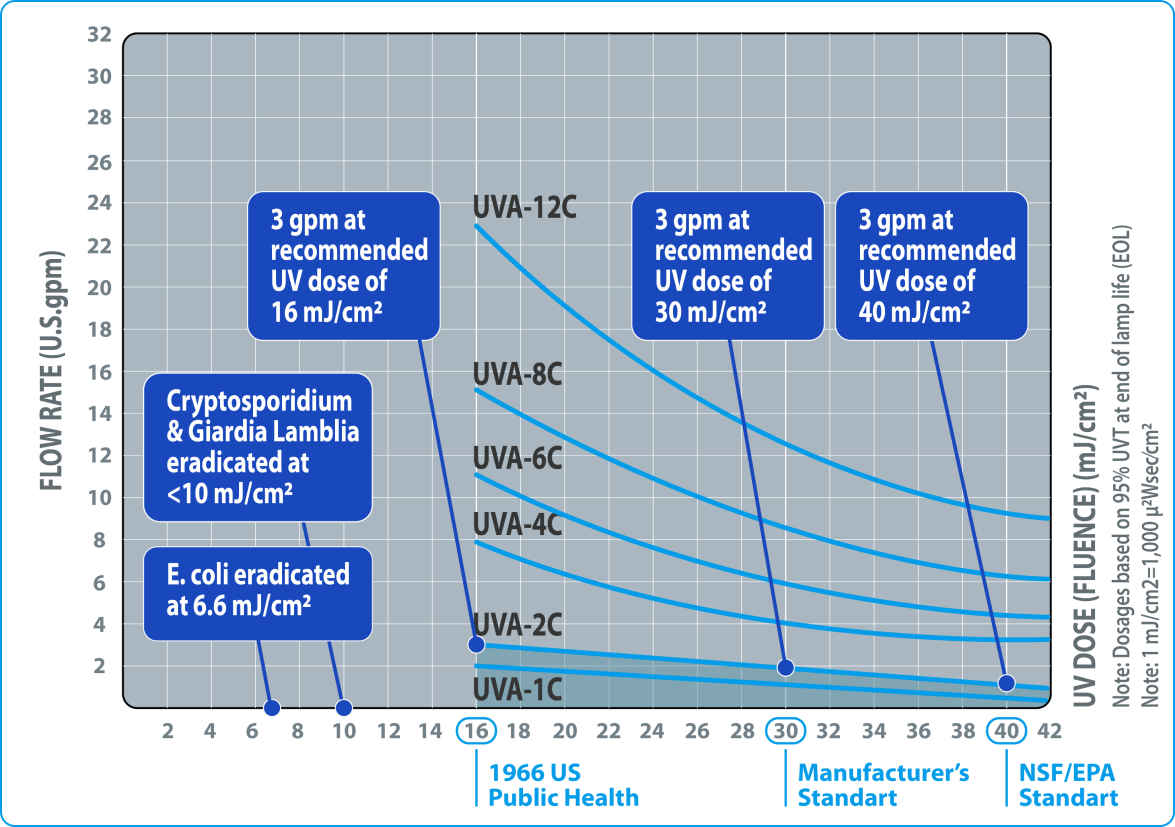

Before selecting your closed vessel UV system, it's worth first understanding what manufacturers mean when they say 'UV dose'. This can be explained by a simple formula where the UV dose is the intensity of the UV light emitted per square area, multiplied by the time the water is in contact with the radiation. The units for this dose are normally given as mJ/cm^2 or mW.s/cm^2, and are commonly referred to as micro-joules.

UV dose = UV light (mW/cm^2) x contact time (s)

The UV dose rate is a key parameter for selecting your UV system as different bacteria and viruses are eradicated at different UV dose rates. This is shown in the below table from POLARIS.

Now we understand the differences in the types of UV systems, and what UV dose means and is used for, we can easily calculate what UV dose you need, and what size UV system is required based on your flow rate.

Example:

A fast food outlet has received a test report that indicates the presence of both E. Coli and coli-forms in their mains water. During peak service times the outlet requires 5 gpm of water to be treated for use in the outlet. The problem for the outlet is that the water connection is in the kitchen with only 10" x 50" space to install a UV system.

Water containing coli-forms must be sanitized to NSF 55 Class A standards. For this application we would opt for our BLACKCOMB-HO high output compact range that is rated to NSF 55. For the given flow rate the LBH6-15XA is best suited to provide the most economical system with the footprint of the UV reactor being only 3.5 " x 20".

| BLACKCOMB (Standart-output) | BLACKCOMB-HO (High-output, compact design) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | LB6-02XA LB6-02A-12V | LB6-03XA LB6-03A-12V | LB6-03XA LB6-06A-12V | LB6-10XA | LB6-15XA | LBH6-05XA | LBH6-10XA | LBH6-15XA | LBH6-25XA | LBH6-40XA | |

| NSF Class A Flow Rate (40J/cm2 @ 70% UVT) | 1.6 GPM | 2.2 GPM | 3.4 GPM | 6.3 GPM | 7.9 GPM | 2.2 GPM | 4.0 GPM | 5.4 GPM | 7.9 GPM | 18.0 GPM | |

| 6.1 lpm | 8.3 lpm | 12.9 lpm | 23.8 lpm | 29.9 lpm | 8.3 lpm | 15.1 lpm | 20.4 lpm | 29.9 lpm | 68.1 lpm | ||

| 0.36 cm3/hr | 0.5 cm3/hr | 0.77 cm3/hr | 1.43 cm3/hr | 1.79 cm3/hr | 0.5 cm3/hr | 0.91 cm3/hr | 1.23 cm3/hr | 1.79 cm3/hr | 4.08 cm3/hr | ||

| Flow Restrictor | Integral | ||||||||||

| Port Size | ½ “FNPT | ½ “MNPT | ¾ “MNPT | ¾ “MNPT | 1 “MNPT | ½ “MNPT | ¾ “MNPT | 1 “MNPT | 1 “MNPT | 1 ½ “MNPT | |

What other factors can impact the performance of your POLARIS or BLACKCOMB UV systems? It is also important to consider the quality of the water being treated as this can impact how much of the radiation is effectively transmitted to sanitize the water. Your UV system can be correctly sized for the flow rate and radiation dosage, but if the background water quality is not considered your disinfection performance may be severely impacted.

Some of the key water quality parameters to consider are:

Turbidity: This is a measure of the general clarity of the water and is commonly measured as nephelometric turbidity units (NTU). The more turbid the water is, the more radiation is absorbed by particles in the water and not used for disinfection. We recommend an NTU of < 1.

Manganese and Iron: These metals, whilst also adding to turbidity if present as precipitated solids, can create fouling in your UV when present as dissolved metals. We recommend a concentration of < 0.05 mg/L for manganese and < 0.3 mg/L for iron.

Hardness: Dissolved salts, calcium and magnesium can make water 'hard'. This can be detrimental to your UV performance with scale forming over time within the UV reactor. We recommend feed water hardness be < 120 mg/L.

Tannins: These are dissolved molecules that can be found in water catchments that have leaves and natural organic matter accumulating in them. Similar to turbidity, tannins can reduce the actual delivered radiation to the E. Coli or coliforms. We recommend tannins be reduced to < 0.1 mg/L.

With a water sample we can recommend and suggest the appropriate pre-treatment to ensure the optimal operation of your POLARIS or BLACKCOMB UV system.