Booster Pump Questions & Answers - Residential and Light Commercial Reverse Osmosis

Do I need a booster pump?

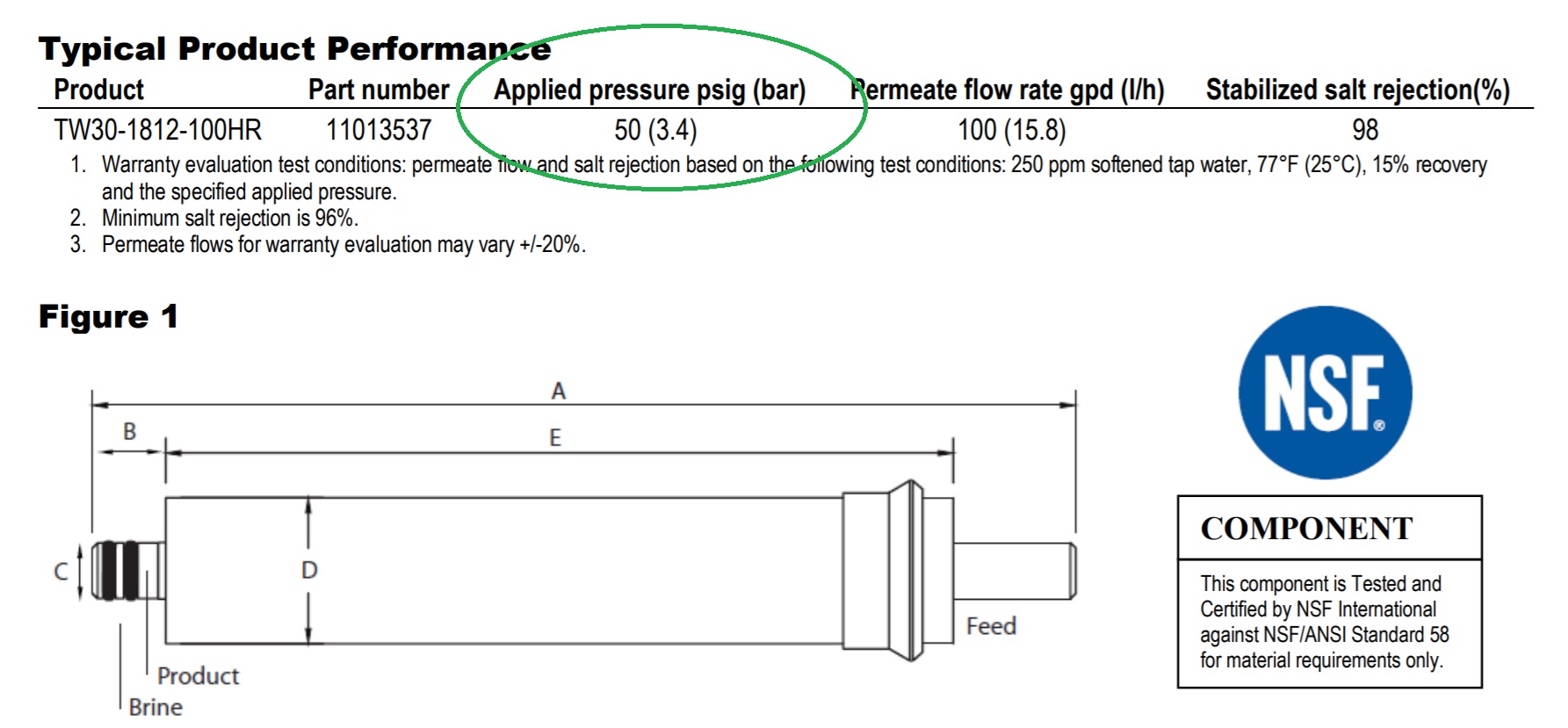

If you're running city water through your RO system, you probably don't need an additional booster pump. Municipalities try their best to maintain water pressure at individual homes at or above 50 PSI, which is exactly what your residential undersink or countertop reverse osmosis membrane requires.

FILMTEC™ TW30-1812-100HR Pressure Rating

Private well systems most commonly have pressurized storage tank and pump systems with 20/40 psi or 30/50 psi on/off pressure settings. This means you will most likely need a booster pump. If you install and run the RO without a pump, when there is no adequate water pressure, more water will be sent down the drain and the contaminant rejection will be low.

Even if you have enough water pressure, booster pumps are necessary sometimes due to excessive tds, high contaminant concentraions (i.e., arsenic, nitrate, chromium), lower temperatures, or a combination of these problems.

Can the pump pull water out of a cistern?

No. The pump’s inlet chamber must be flooded with water for it to operate properly. This translates to at least 5 PSI inlet water pressure to the pump. Use a gravity feed system using an atmospheric tank and then use the booster pump to further increse the pressure.

Will the pump work even without electricity?

As long as there is feed water pressure, the pump will not stop forward flow of water even if the motor is turned off. Be sure the system has positive means of shutting off water supply such as an auto shutoff valve or a solenoid valve. See booster pump installation diagrams here.

Where should a pump be installed?

A booster pump is most commonly installed in a reverse osmosis water system between the stage 1 sediment filter and the stage 2 carbon filter. US booster pump manufacturer Aquatec recommends that the pump should always be mounted prior to the carbon pre-filter to prevent carbon particles from entering the pump chambers and possibly causing clogging.

Most pumps can be mounted horizontaly or vertically. However, if vertical mounting is needed, make sure to place the pumphead facing up to avoid performance reduction. If the pumphead is mounted upside down, air entrapment may reduce the operational performance by up to 15%.

Booster pump ports should be connected to flexible tubing. If connected to rigid pipes, pump’s normal oscillation may transmit through the plumbing causing vibration noise, and possibly loosening or cracking components.

Can the pump run continously 24/7?

This will depend on the model of the pump. The Aquatec CDP series pumps are designed for continuous duty. If used for intermittent duty cycle. Make sure that “off” periods are greater than 60 seconds.

An RO design with an auto shutoff valve should shut off the system when it reaches appromimately 60% of the boosted line pressure (e.g., a boosted pressure of 70 PSI will = a maximum ro water tank pressure of 42 PSI). RO's with a high-pressure switch (deactivated at 40, 60 or 80 PSI) cuts off power to the pump when the pressurized water storage tank has reached the capacity.

What boosted pressure can I expect?

Most Aquatec boost pumps are designed to limit the maximum output pressure to 110 psi, to protect the membrane and other components from damage. The normal operating pressure as measured after the pump, and before the membrane, will be approximately 80 psi. The flow rate of the 6800 series pump during operation is about 500 ml/min. The 8800 is double that flow. If these parameters are not being met, please check the following:

1.Is the pump properly sized to handle the production rate of the membrane, plus the brine flow allowed by the restrictor (usually 4 or 5 times the permeate production)?

2. Is the system receiving adequate feed water? The pump’s inlet chamber must be flooded to prevent performance robbing air ingestion into the compression chambers.

3. Debris entering the pump, such as residue from an activated carbon filter improperly located on the inlet side of the pump, may restrict the pumping operation.

What flow rates can I expect from the RO faucet?

Flow rate from your RO drinking water faucet should be approximately 0.5 GPM if the system is operating properly. Most RO faucets will flow at approximately 1 GPM. The loss of flow from the post coconut shell carbon filter, tubing length, etc. can drop you to the ½ GPM range.

Flow rate from your RO drinking water faucet should be approximately 0.5 GPM if the system is operating properly. Most RO faucets will flow at approximately 1 GPM. The loss of flow from the post coconut shell carbon filter, tubing length, etc. can drop you to the ½ GPM range.

When should the pump be serviced?

Every Year: Check system against operating standards.

Every 2-3 Years: Replace diaphragm and check against operating standards.

References:

-

WECO HYDRA RO Manual. 2017.

- Horner, Allan. “Love Plumbing & Remodel of Bellevue & Bothell WA, Terry Love.” Love Plumbing & Remodel of Bellevue & Bothell WA, Terry Love, 12 Sept. 2012, terrylove.com

- FILMTEC. DOW FILMTEC Membranes, www.dow.com.

- “TROUBLE SHOOTING GUIDE FOR R.O. BOOST PUMP SYSTEMS .” Aquatec, www.aquatec.com.

- “OPERATIONAL AND INSTALLATION GUIDELINES “CDP” SERIES BOOSTER PUMP .” Aquatec, www.aquatec.com.